Cleaning Validation is an important task in pharma manufacturing. It ensures that companies are cleaning their equipment well for production of high-quality medicines and other pharma products. As regulatory bodies lay down cleaning protocols and guidelines, it is important that businesses verify their cleaning processes to ensure proper compliance. Agencies like US FDA, EU EMA, MHRA, etc provide strict guidelines to ensure proper cleaning in pharma manufacturing facilities and environment. It is an essential process to limit cross-contamination of pharma products thereby upholding superior product quality.

Necessity of Pharma Cleaning Validation

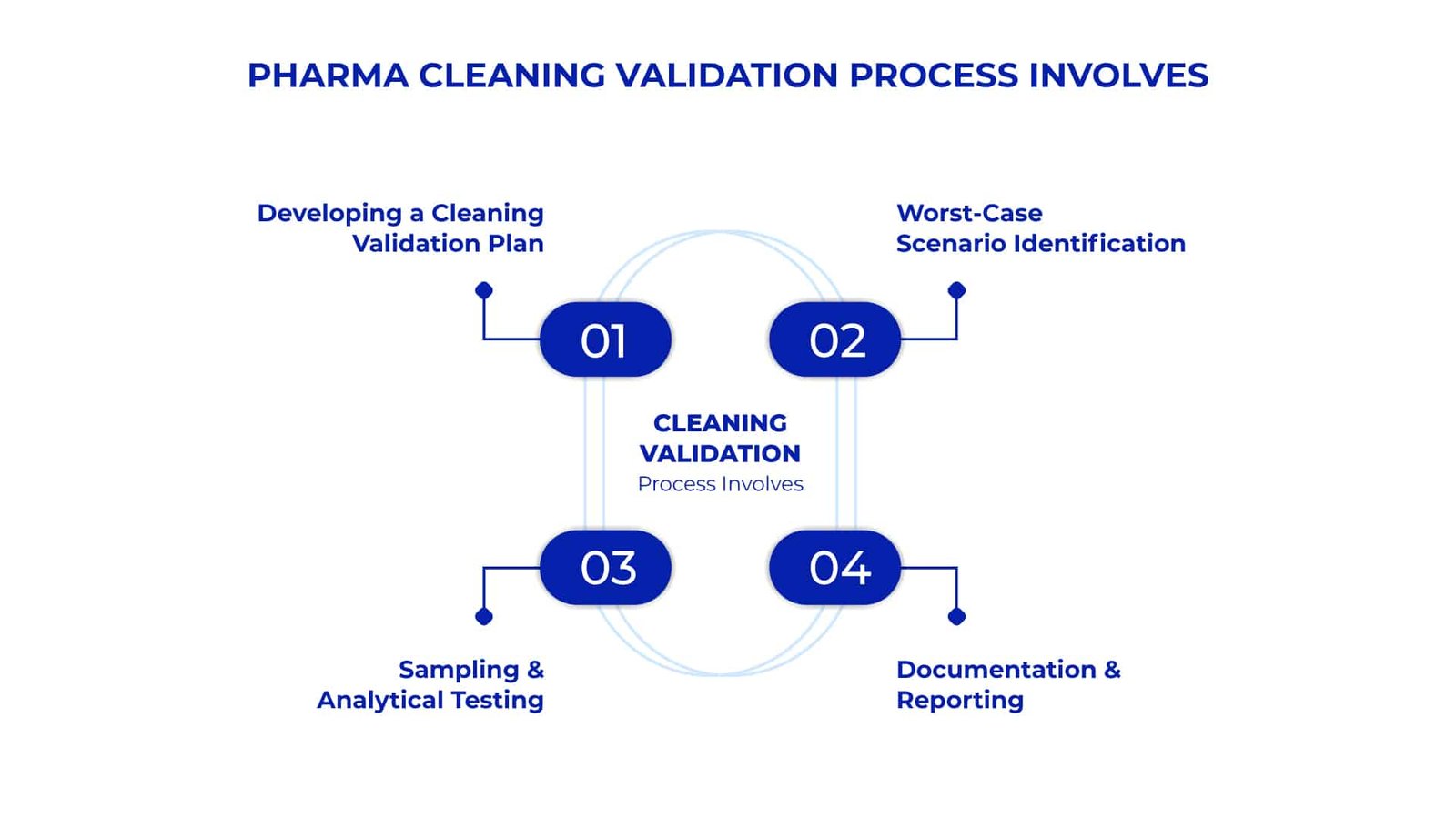

It is important that companies adopt excellent cleaning validation procedures to comply with Good Manufacturing Practices (GMP). Cleaning validation ensures consistent removal of API and excipient residues with cleaning agents according to their predefined and acceptable levels. The cleaning validation process usually involves:

- Developing Cleaning Validation Plan: First, a comprehensive cleaning plan needs to be defined that involves the cleaning procedure, the acceptance criteria to be met, the protocols of cleaning validation, and so on.

- Worst-Case Scenario Identification: It is important that the “worst-case’ scenario is identified for setting up a perfect cleaning validation process. With broad understanding of the situation, an elaborate cleaning process is put into place.

- Sampling & Analytical Testing: After the cleaning process is completed, the surface of the equipment is sampled to analyse residual contaminants. The testing process is integral to understand if the cleaning was effective and left no high level of residue behind.

- Documentation & Reporting: Documentation of the cleaning process is essential for regulatory submissions. It outlines the entire cleaning process, API, excipient, cleaning agent details, the amount of residue left, etc to highlight if the quality of the product is appropriate.

Challenges in Maintaining Regulatory Compliance

Despite the importance of cleaning validation, maintaining regulatory compliance presents several challenges:

- Complexity of Equipment and Products: The wide variety of equipment used in pharmaceutical manufacturing, coupled with the complexity of modern drug formulations, makes cleaning validation a demanding task. Different equipment and products may require customized cleaning procedures and validation strategies.

- Resource Intensiveness: Cleaning validation is resource-intensive, requiring significant time, labour, and expertise. This can strain resources, particularly for smaller companies or those with limited technical staff.

- Data Management: Proper documentation and data management are crucial for demonstrating compliance. Managing large volumes of data, particularly in a manual or paper-based system, can be challenging and prone to errors.

- Regulatory Scrutiny: Regulatory agencies scrutinize cleaning validation processes during inspections. Any gaps or deviations in the validation process can lead to costly delays, product recalls, or penalties.

Leveraging AmpleLogic Cleaning Validation Software

AmpleLogic Cleaning Validation software is an advanced solution that takes care of pharma cleaning validation processes. The software streamlines the evaluation process enhancing productivity, ensuring product quality and compliance. AmpleLogic Cleaning Validation Software is a perfect remedy for pharma regulatory compliance. It comes with some unique features that makes it all the more reliant.

Indulge in the Features!

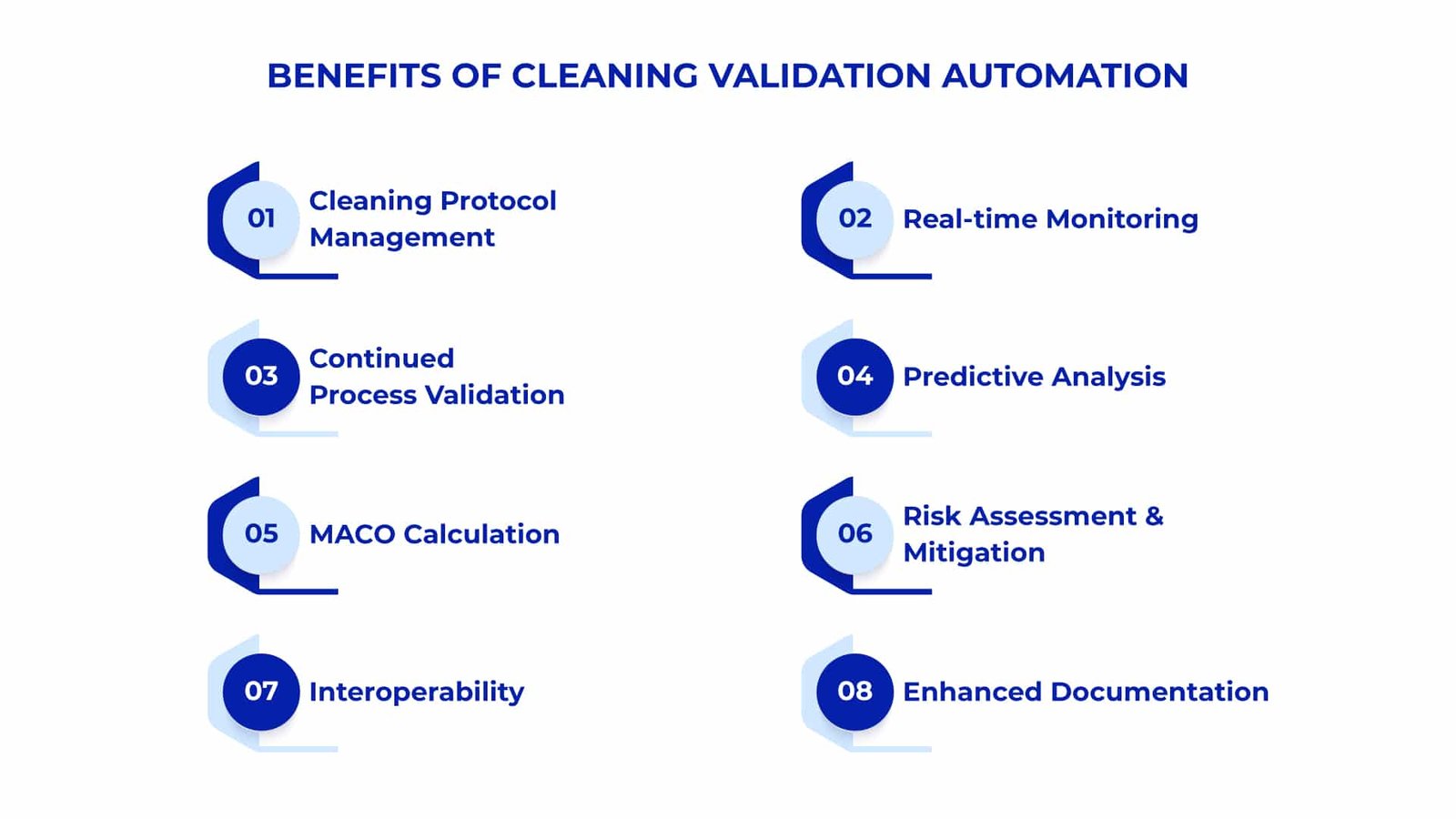

- Protocol Management: Creates detailed protocols for cleaning validation, defining acceptance criteria, sampling methods, and procedures. Ensures accurate documentation and seamless execution for regulatory compliance.

- Real-time Alerts: Monitors critical parameters like cleaning agent concentration and temperature, triggering alerts for deviations to enable immediate corrective actions.

- Data Collection and Analysis: Automates data collection and analysis, identifying trends and risks, optimizing cleaning processes, and ensuring compliance with advanced analytics.

- Continued Process Validation: Enables continuous verification of process performance, integrating seamlessly with other AmpleLogic products to streamline operations and eliminate redundancy.

- Risk Assessment and Mitigation: Assesses and mitigates risks like cross-contamination, ensuring regulatory compliance and safeguarding product quality.

- Predictive Analysis: Uses advanced algorithms to anticipate issues and enhance efficiency through proactive process improvements.

- MACO Calculation: Determines acceptable residue levels to prevent contamination, ensuring safety in subsequent manufacturing batches.

- Interoperability: Offers excellent integration with other systems via API, enabling real-time data sharing and seamless operation with AmpleLogic’s solutions.

- Report Generation: Produces comprehensive validation reports essential for regulatory submissions, confirming process efficiency and compliance.

- Knowledge Transfer: Centralizes critical information, standardizes workflows, and provides access to historical data for continuous improvement.

- Regulatory Compliance: Ensures adherence to FDA, PDA, EMA standards by automating workflows, creating protocols, and generating reports, mitigating risks while maintaining data integrity.

- Predictive Analytics: Advanced data analytics can predict potential risks and optimize cleaning processes by analysing historical data. This helps in identifying trends, improving process efficiency, and preventing contamination.

- Real-Time Monitoring: Automated systems enable real-time monitoring of cleaning processes, ensuring immediate detection and correction of any deviations. This enhances compliance by maintaining consistent cleaning standards.

- Enhanced Documentation: Digital solutions streamline documentation by automatically recording and storing data, reducing the risk of human error, and ensuring quick retrieval during audits.

Ensuring regulatory compliance in cleaning validation is a critical aspect of pharmaceutical manufacturing. It requires thorough understanding of regulatory requirements, meticulous planning, and effective execution. By embracing AmpleLogic’s Cleaning Validation software, pharmaceutical companies can overcome challenges in cleaning validation, promoting regulatory compliance and ensuring highest standards of product quality and safety. In an industry where patient safety is paramount, maintaining rigorous cleaning validation processes is not just a regulatory obligation—it’s a moral imperative.