Is your batch release process still a manual task of checklists, paper trails, and follow-up emails? You’re not alone.

Releasing a pharmaceutical batch is one of the most important quality steps before the product reaches patients. Traditionally, this step involves reviewing huge amounts of paperwork, like batch manufacturing records and lab test results. It is often slow and prone to human error. But by adding automation to this process, especially through systems like the Annual Product Quality Review (APQR). A modern APQR is a real-time control tower for continuous quality assurance. And that includes batch release readiness, one of the most critical checkpoints in pharmaceutical manufacturing.

Let’s get to know how automation can make batch release smarter, faster, and compliant, right from your APQR dashboard.

Benefits of Batch Release Checklist in Pharma

Before you jump into automation, it’s important to know why having a good checklist matters in the first place. Whether you use a manual system or an automated APQR dashboard, a batch release helps teams follow the right steps, stay compliant, and avoid delays. Here’s how the batch release helps in both manual and digital formats:

| Checklist Benefits | Manual Process | With APQR Automation |

|---|---|---|

| Regulatory Compliance | Manual checks for cGMP, FDA, and ICH before release. | Digital checklist enforces regulatory steps with system controls and audit logs. |

| Quality Assurance | Confirms quality specs like assay and sterility, but may rely on human tracking. | QA steps are in-built into the workflow, auto-validated, and time-stamped for accuracy. |

| Standardization Across Sites | Varies between plants or teams, with a risk of missed steps or format inconsistencies. | Unified templates ensure consistent execution across all manufacturing locations. |

| Accountability & Audit Trail | Handwritten sign-offs can be misplaced or delayed. | Digital signatures are secure, time-stamped, and Part 11-compliant for traceability. |

| Risk Mitigation | Missing data or unresolved deviations may go unnoticed until the final QA review. | System flags incomplete tasks early, minimizing the risk of batch failure or recall. |

| Cross-Functional Alignment | Coordination depends on email chains or manual updates. | Real-time dashboard connects QC, QA, Production & Regulatory Affairs seamlessly. |

| Real-Time Tracking | Requires manual status updates, prone to delays. | Live checklist updates show what’s done, pending, or overdue, instantly. |

| Error Reduction | High chance of missed fields, signatures, or attachments. | Automation ensures mandatory steps are completed. |

| System Integration | Often siloed, needs double entry into QMS, LIMS, ERP, etc. | Auto-pulls data from integrated systems, zero redundancy, full visibility. |

| Faster Release Timelines | Batch review takes longer due to fragmented information and manual follow-ups. | Speedy review cycles driven by connected data and automated workflows. |

| Actionable Insights for APQR | Limited visibility into trends or bottlenecks. | Tracks recurring issues across batches, useful for continuous improvement in APQR. |

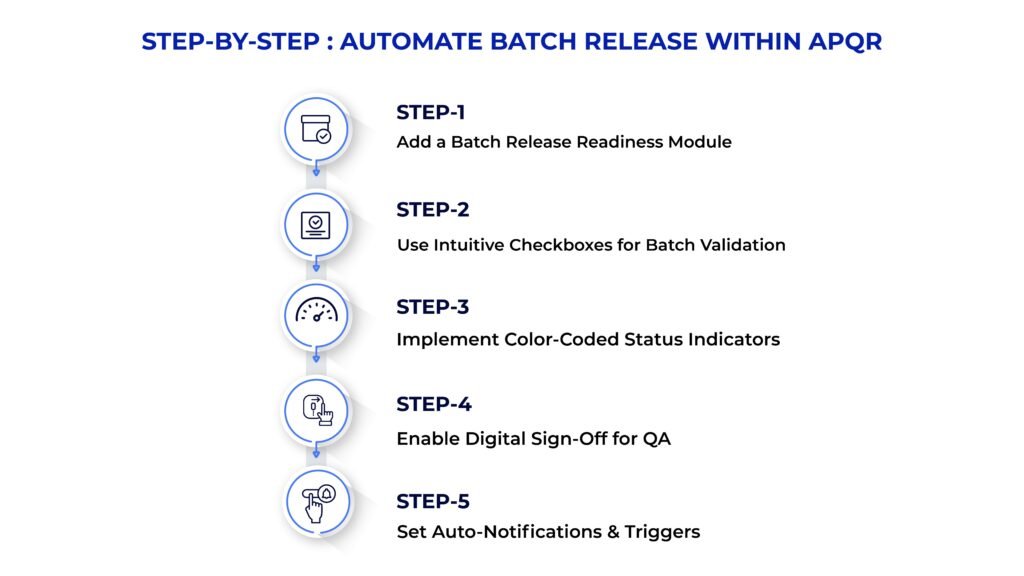

Step-by-Step: Automate Batch Release Within APQR

Automating batch release through your Annual Product Quality Review (APQR) process does not require changing your workflow; it just needs a smarter, more connected setup. Here’s how to do it, step by step.

1. Add a Batch Release Readiness Module

Create a dedicated module in your APQR dashboard labeled Batch Release Readiness. This module serves as a live checklist and approval gateway. Think of it as a digital control department where QA teams can monitor everything in real-time. This module should:

- Act as a live checklist tailored to your SOPs.

- Display the status of each batch in progress.

2. Use Intuitive Checkboxes for Batch Validation

Design the checklist with clearly defined checkpoints:

- Completed BMR/BPR Confirms that the batch manufacturing and packaging records are complete, reviewed, and meet protocol.

- Approved Analytical Data Ensures that all required quality control tests (e.g., assay, dissolution, sterility) are approved and within specification.

- Deviations and CAPAs Closed Indicates that any deviations from SOPs and their corrective or preventive actions have been addressed, reviewed, and closed.

- Stability/Retention Samples Logged

Verifies that product samples for stability and retention studies are stored properly, as per regulatory timelines. - Regulatory Label Verification Completed

Confirms that the final labels comply with market-specific regulatory submissions and approvals.

Each checkbox acts as both a validation point and a data anchor. Once all the boxes are ticked, the system recognizes that the batch is technically ready to move forward.

3. Implement Color-Coded Status Indicators

Visuals matter. Color codes help QA teams scan the readiness state:

- Green – Complete

- Yellow – Pending Review

- Red – Missing or Incomplete

This design minimizes back-and-forth communication, thereby accelerating decision-making.

4. Enable Digital Sign-Off for QA

Once everything’s green, activate a digital sign-off feature. This adds an e-signature from the QA authority, creating a time-stamped, 21 CFR Part 11 compliant trail. The benefits are multifold:

- Clear documentation of who approved the batch and when.

- Tamper-evident records.

- Immediate audit readiness.

5. Set Auto-Notifications & Triggers

The system can instantly notify stakeholders when:

- A batch is ready for QA review

- A checklist item is pending beyond the SLA

- A batch is blocked due to unresolved issues

These smart alerts eliminate bottlenecks, ensuring swift batch turnaround.

Final Thoughts

Batch release has always been required, but it doesn’t necessarily need to be done manually. With an automated checklist integrated into your APQR, you achieve quicker releases, better compliance, and neater audits.

It’s time to have your APQR work beyond doing annual reporting. Have it drive batch readiness in real time.