Glossary

AI Manufacturing

What is AI in Manufacturing?

AI in manufacturing involves using machine learning solutions and deep learning neural networks to streamline processes, improve data analysis, and speed up decision-making. It is a great technology for predictive maintenance, resource planning, and process optimisation in regulated industries.

Artificial Intelligence brings intelligent automation to manufacturing floors, enabling machines to adapt, learn from data, and respond in real time. In pharmaceutical environments, where precision and consistency are critical, AI helps improve equipment uptime, reduce manual intervention, and accelerate time-to-market. With predictive algorithms, manufacturers can shift from reactive to proactive maintenance strategies, preventing unplanned downtimes and saving

Important areas where AI is used in manufacturing include:

Predictive Maintenance: Detects signs of equipment failure before they occur.

- Real-Time Quality Control: Identifies defects or inconsistencies during production.

- Demand Forecasting: Uses historical and real-time data to predict market needs.

- Resource Optimization: Plans energy usage, labor deployment, and raw material flow efficiently.

- Digital Twin Technology: Simulates production environments to test changes virtually before implementing them on the floor.

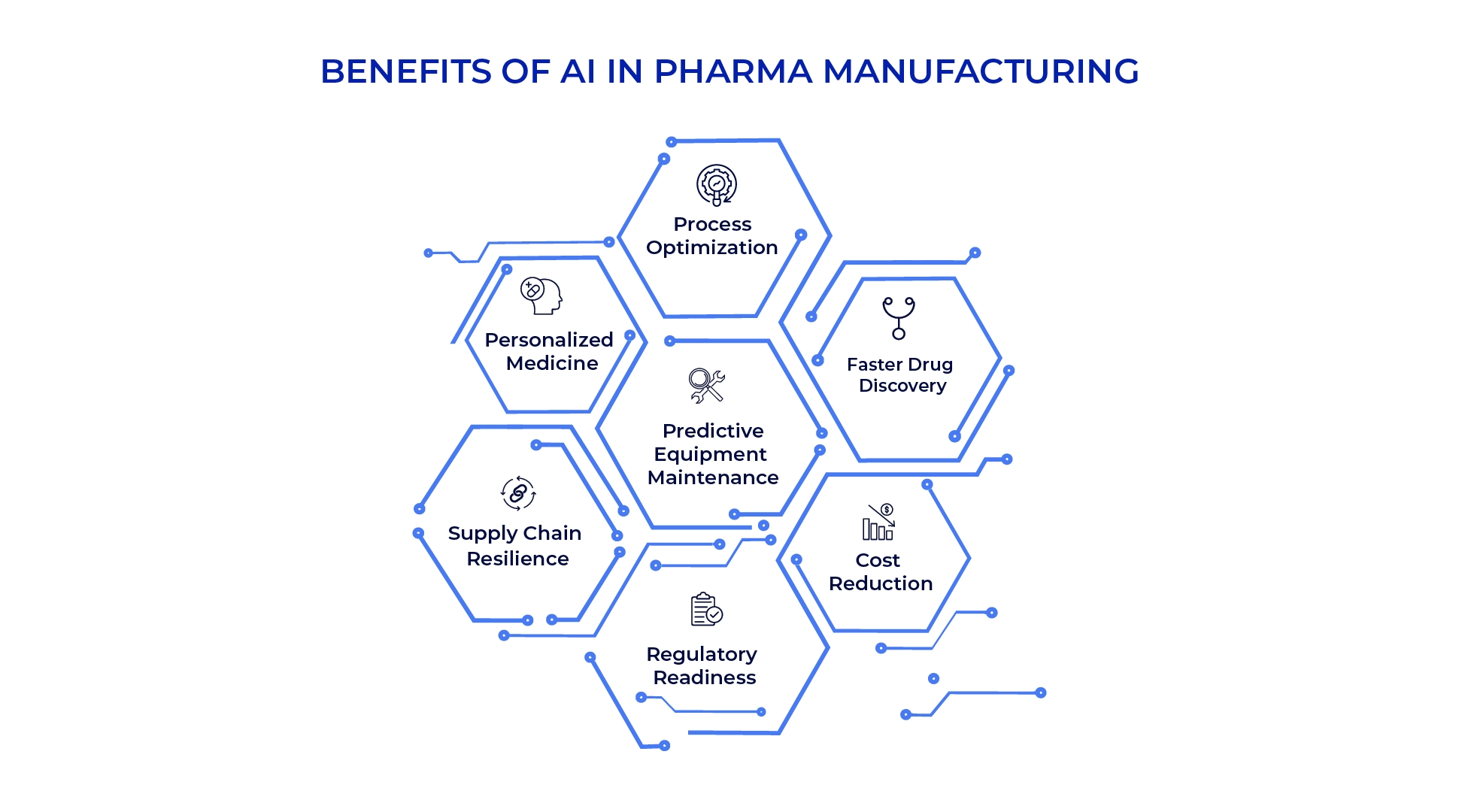

What are the benefits of AI in pharma manufacturing?

Artificial intelligence optimizes the manufacturing process of pharma products while ensuring peak quality with reduced costs. AI-powered predictive maintenance of equipment and supply chain management fosters overall efficiency. The technology also helps produce personalised medicines based on patient data, accelerates drug discovery, and ensures regulatory compliance.

The pharmaceutical industry, known for stringent quality standards and high R&D costs, can greatly benefit from AI at every stage of production. From drug development to batch release, AI brings speed, precision, and actionable intelligence.

Benefits of AI in pharma manufacturing:

- Process Optimization

- Personalized Medicine

- Predictive Equipment Maintenance

- Faster Drug Discovery

- Supply Chain Resilience

- Cost Reduction

- Regulatory Readiness

By integrating AI, pharma manufacturers not only boost operational efficiency but also improve patient outcomes by making medicine more accessible, accurate, and responsive to real-world needs.

How can AI help in pharma regulatory compliance?

AI technology can easily help monitor pharmaceutical manufacturing processes by keeping track of detailed data and records. This way, deviations and risks can be immediately identified, facilitating quick corrective actions. AI can further streamline documentation and enhance regulatory compliance by reducing human errors.

Compliance in the pharmaceutical sector involves more than just following protocols; it requires robust systems to ensure traceability, accountability, and real-time reporting. This is where AI becomes an indispensable tool. Here’s how AI helps ensure regulatory compliance:

- Automated Monitoring: AI tracks every stage of production, flagging anomalies as soon as they occur, which helps in real-time deviation management.

- Risk Detection: Machine learning algorithms analyze historical data to predict and prevent high-risk events or compliance breaches.

- Document Control: AI-enabled Document Management Systems (DMS) maintain version control, automate approvals, and ensure SOPs are followed.

- 21 CFR Part 11 Compliance: AI ensures secure, timestamped digital records with audit trails and electronic signatures in line with regulatory mandates.

- CAPA and Change Control: AI supports root cause analysis and recommends corrective and preventive actions (CAPA) to reduce recurring compliance issues.

- Reduced Human Error: By automating routine documentation and data entry tasks, AI minimizes the chances of manual mistakes, ensuring more accurate records.

Ultimately, AI empowers pharmaceutical manufacturers to go beyond compliance, making regulatory adherence proactive, data-driven, and sustainable. Schedule a free demo today to see how Amplelogic can help with AI-integrated software in your manufacturing units. Also, you can visit our Amplelogic Resource page for more such informative glossary terms!