At AmpleLogic, we closely monitor regulatory actions and trends in the pharmaceutical industry. In the highly regulated pharmaceutical industry, compliance with CGMP standards is a fundamental pillar of patient safety, product quality, and business reputation. Each year, several companies receive FDA Warning Letters for non-compliance with Current Good Manufacturing Practice (CGMP) standards.

These lapses are common regulatory compliance gaps that, if overlooked, can lead to product recalls, operational delays, and long-term reputational risks. The reality is that most of these issues can be avoided with the right systems in place.

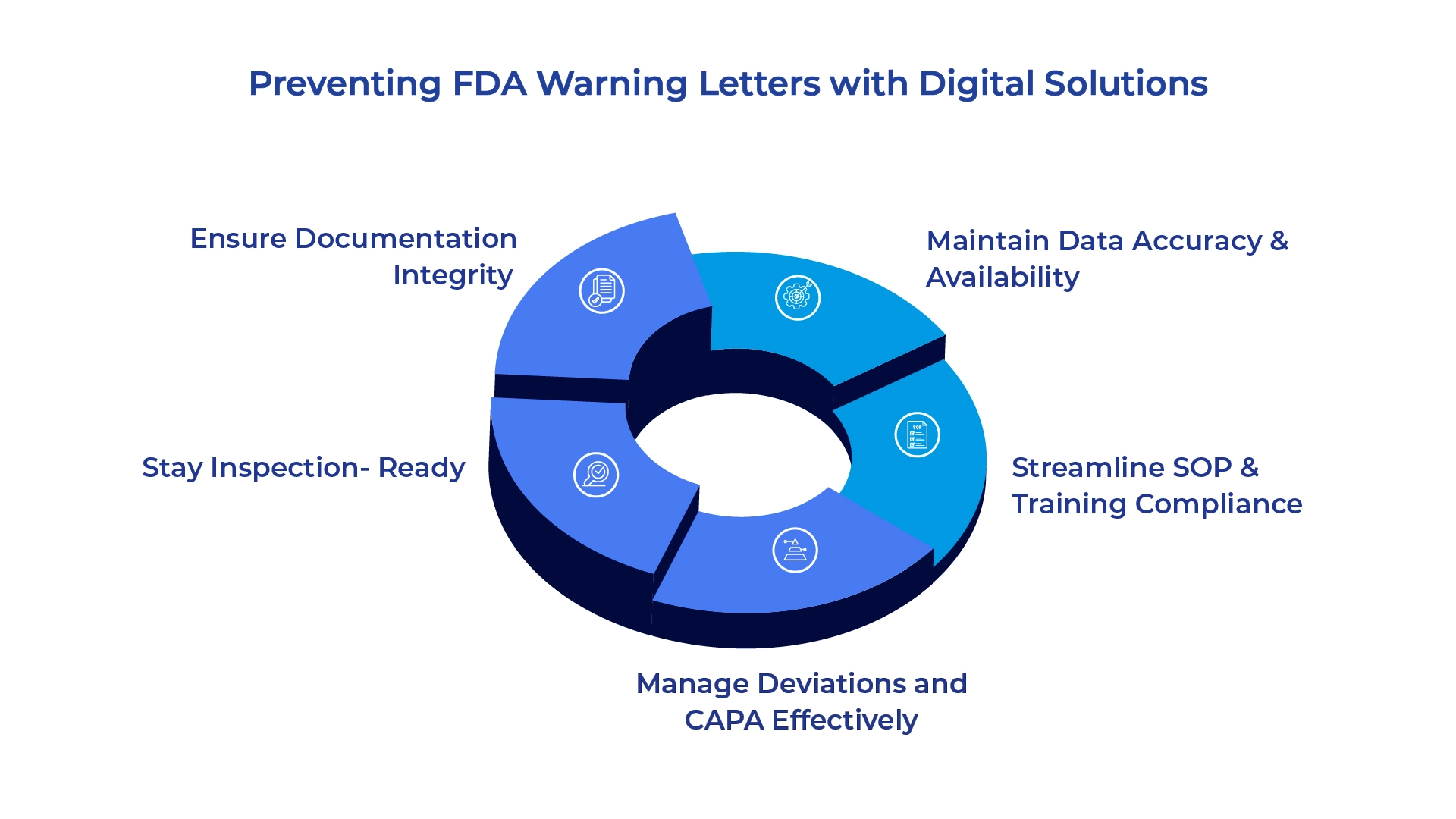

The good news? With the right digital systems and a proactive quality culture, these issues are entirely preventable. At AmpleLogic, we have developed a suite of digital solutions specifically designed to close these compliance gaps, keep companies audit-ready, and future-proof operations. Let’s explore the most common FDA findings and how AmpleLogic’s technology addresses each one.

11 Common FDA Warning Letters & Solutions

Below, we have integrated similar FDA warning letter findings into cohesive themes and provided accurate insights into each area.

1. Inadequate Raw Material & Supplier Management Qualification:

FDA Findings:

- Failure to test raw materials (APIs, excipients) for identity, purity, and contamination.

- Over-reliance on supplier certificates of analysis (COAs) without independent verification.

- Lack of testing for toxic impurities like diethylene glycol (DEG), ethylene glycol (EG), and methanol.

How AmpleLogic Helps:

Our electronic Quality Management System (eQMS), as well as LIMS, ensures every material undergoes systematic incoming inspection.

- High-risk ingredients are automatically flagged for additional impurity tests, such as DEG/EG and methanol.

- Supplier qualification workflows automate periodic requalification audits, while validated supplier records are maintained for traceability.

2. Quality Unit (QU) Oversight & Documentation

FDA Findings:

- Products are released before completion of all quality control tests.

- Lack of reserve sample management for raw materials and finished goods.

- No annual product reviews (APRs) or poor document control.

- Inadequate control over master production records and critical system access.

AmpleLogic’s Quality Management System (QMS) and Batch Release Management solutions ensure that no batch moves forward without full QC release and electronic approvals.

- Our system tracks storage, retrieval, and audit readiness.

- The QMS digitizes APQR generation, manages change control, deviations, and CAPA, and ensures every document change is logged with a full audit trail.

- Access controls guarantee that only authorized personnel can edit master records, while task-driven dashboards help QU users monitor batch disposition, investigations, and quality KPIs in real time.

3. Process Validation & Cleaning Validation

FDA Findings:

- Manufacturing processes are launched without proper validation.

- Unqualified equipment and missing cleaning validation.

- Undefined critical process parameters and failure to demonstrate process consistency.

How AmpleLogic Helps:

Our Cleaning Validation software streamlines protocol development, execution, and review, tracking the validation lifecycle from IQ/OQ/PQ to PPQ.

- Cleaning Validation Modules maintain cleaning validation plans, schedule requalification, and ensure traceability of cleaning records.

- This lifecycle approach ensures scientific evidence is always available to prove process control, cleaning effectiveness, and batch consistency, keeping companies ready for any audit or inspection.

4. Laboratory Controls & Data Integrity

FDA Findings:

- Testing methods are not validated to detect contaminants.

- Failure to maintain original, complete, and accurate laboratory records.

- Fabrication of laboratory investigations and lack of traceable analytical data.

How AmpleLogic Helps:

AmpleLogic’s Laboratory Information Management System (LIMS) ensures all analytical methods are validated and suitability testing is documented and traceable.

- Every action-edit, deletion, or addition is timestamped and logged, making data tampering easily detectable.

- Role-Based Access Controls (RBAC) and regular system validations further protect electronic records, ensuring compliance with 21 CFR Part 11.

5. Stability Testing & Expiry Date Justification

FDA Findings:

- No stability data to support expiry dates.

- Absence of formal stability programs and incomplete testing (e.g., only assay done, no microbiology or impurity studies).

- Amplelogic Stability system manages stability protocols, pulls batches into annual ongoing stability programs, and schedules microbiological and impurity testing automatically.

Alert systems flag upcoming study deadlines and missing attributes, ensuring proactive compliance. All stability data is systematically recorded, supporting scientifically justified shelf-life and retest dates in line with FDA and ICH guidelines.

6. Finished Product Testing & Batch Records

FDA Findings:

- Failure to perform complete testing (identity, strength, quality, purity) of drug products before release.

- Incomplete batch production and control records.

How AmpleLogic Helps:

Our electronic Batch Manufacturing Records (eBMR) records every production step, signature, and deviation in real time, preventing batch closure until all required steps and checks are digitally completed. This approach guarantees that no significant manufacturing or packing step is left undocumented.

7. Environmental Monitoring & Aseptic Processing Controls

FDA Findings:

- Inadequate laboratory controls and impurity monitoring.

- Poor aseptic practices and flawed cleanroom behavior.

- Improper placement and inconsistent use of environmental monitoring probes.

AmpleLogic’s Solution:

Our LIMS ensures scientifically justified specifications are linked to each batch, with automated stability study management tracking impurity levels throughout the product lifecycle.

- The Electronic Batch Record (EBR) system mandates real-time aseptic behavior checklists and deviation capture during production.

- Environmental Monitoring Systems are integrated with cleanroom layouts, ensuring probe placement at validated locations.

- Automated alarms and deviation triggers enable immediate investigation and CAPA linkage for environmental excursions, while preventive maintenance modules schedule facility inspections to ensure ongoing integrity.

8. Facility Design, Maintenance & Change Management

FDA Findings:

- Failure to design and maintain facilities to minimize contamination risk.

- Inadequate process and cleaning validation.

- Lack of formal change management procedures.

How AmpleLogic Helps:

Our eLogbook and eBMR track batch activities, maintenance, repairs, and cleaning activities in real time. Preventive maintenance schedules, equipment status management, and prompt deviation recording reduce contamination risks.

Our eQMS automates change request submissions, risk assessments, impact evaluations, approval workflows, and post-implementation reviews. This structured approach ensures that all changes are documented, justified, and do not compromise product quality or CGMP compliance.

9. Complaint Handling, CAPA & Continuous Improvement

FDA Findings:

- Poor investigation of complaints, inadequate CAPA, and failure to extend investigations to other batches or environmental factors.

- Systemic quality culture deficiencies and lack of integrated quality systems.

How AmpleLogic Helps:

Our QMS automates complaint logging, root cause analysis, and CAPA, ensuring investigations are comprehensive and extend to all potentially affected batches and environments.

- Integrated modules for Complaints, Deviations Management, CAPA, Change Control, and Risk Management create a single ecosystem for proactive compliance.

- Executive dashboards and real-time compliance monitoring enable management to review quality health metrics and intervene early.

- Built-in risk assessment templates and continuous training modules encourage a culture of quality and risk-based thinking, aligned with ICH Q9 and FDA guidelines.

10. Regulatory Information & Label Management

FDA Findings:

- Marketing of unapproved or misbranded drugs.

- Incorrect or incomplete labeling, including drug facts and warnings.

- Failure to investigate Out-of-Specification (OOS) or Out-of-Trend (OOT) results

How AmpleLogic Helps:

Our Regulatory Information Management System (RIMS) maintains up-to-date compliance with monographs, TFM/OTC standards, and FDA approvals. Amplelogic’s QMS also helps in automating the process of investigating OOS & OOT results, ensuring that a thorough root cause analysis is conducted.

11. Change Control and Impact Assessment

FDA Issues:

- Lack of formal change management procedures for processes, equipment, or facilities.

- Changes implemented without proper risk assessment or documentation.

AmpleLogic’s Solutions:

AmpleLogic’s Change Control system automates submission, risk assessment, approval workflows, and post-implementation reviews. It ensures all changes are documented, justified, and their impact on product quality is evaluated and approved before implementation.

Conclusion: Digital Transformation as a Compliance Enabler

The recurring themes in FDA warning letters, whether related to raw material testing, data integrity, process validation, or facility maintenance, underscore the need for robust, integrated quality systems. AmpleLogic’s digital solutions are designed to address these gaps holistically, making compliance systematic, traceable, and proactive.

By adopting these technologies, pharmaceutical companies not only avoid costly warning letters from the FDA and recalls but also build a culture of quality that supports innovation, operational excellence, and, most importantly, patient safety.

Ready to future-proof your compliance? Get a free demo from AmpleLogic to learn how our digital solutions can help you stay audit-ready and ahead of regulatory expectations.