In pharmaceutical manufacturing, ensuring consistent production of high-quality products is paramount. One of the key elements in achieving this goal is the rigorous control of Critical Process Parameters (CPPs). These parameters, including variables such as temperature, pH, pressure, and mixing speed, are crucial in determining the quality and efficacy of pharmaceutical products. To effectively manage these parameters and ensure compliance with regulatory standards, many manufacturers are turning to Manufacturing Execution Systems (MES).

Understanding Critical Process Parameters (CPPs)

In pharmaceutical manufacturing, ensuring consistent production of high-quality products is paramount. One of the key elements in achieving this goal is the rigorous control of Critical Process Parameters (CPPs). These parameters, including variables such as temperature, pH, pressure, and mixing speed, are crucial in determining the quality and efficacy of pharmaceutical products. To effectively manage these parameters and ensure compliance with regulatory standards, many manufacturers are turning to Manufacturing Execution Systems (MES).

Importance of Critical Process Parameters

Control of CPPs is fundamental in pharmaceutical manufacturing for several reasons:

- Ensures Product Quality: By controlling CPPs, manufacturers can maintain the quality of the final product, ensuring it meets all regulatory and safety standards.

- Consistency and Reliability: Properly managed CPPs lead to consistent production processes, reducing variability and increasing reliability.

- Regulatory Compliance: Regulatory bodies require documentation and control of CPPs to ensure that pharmaceutical products are safe and effective.

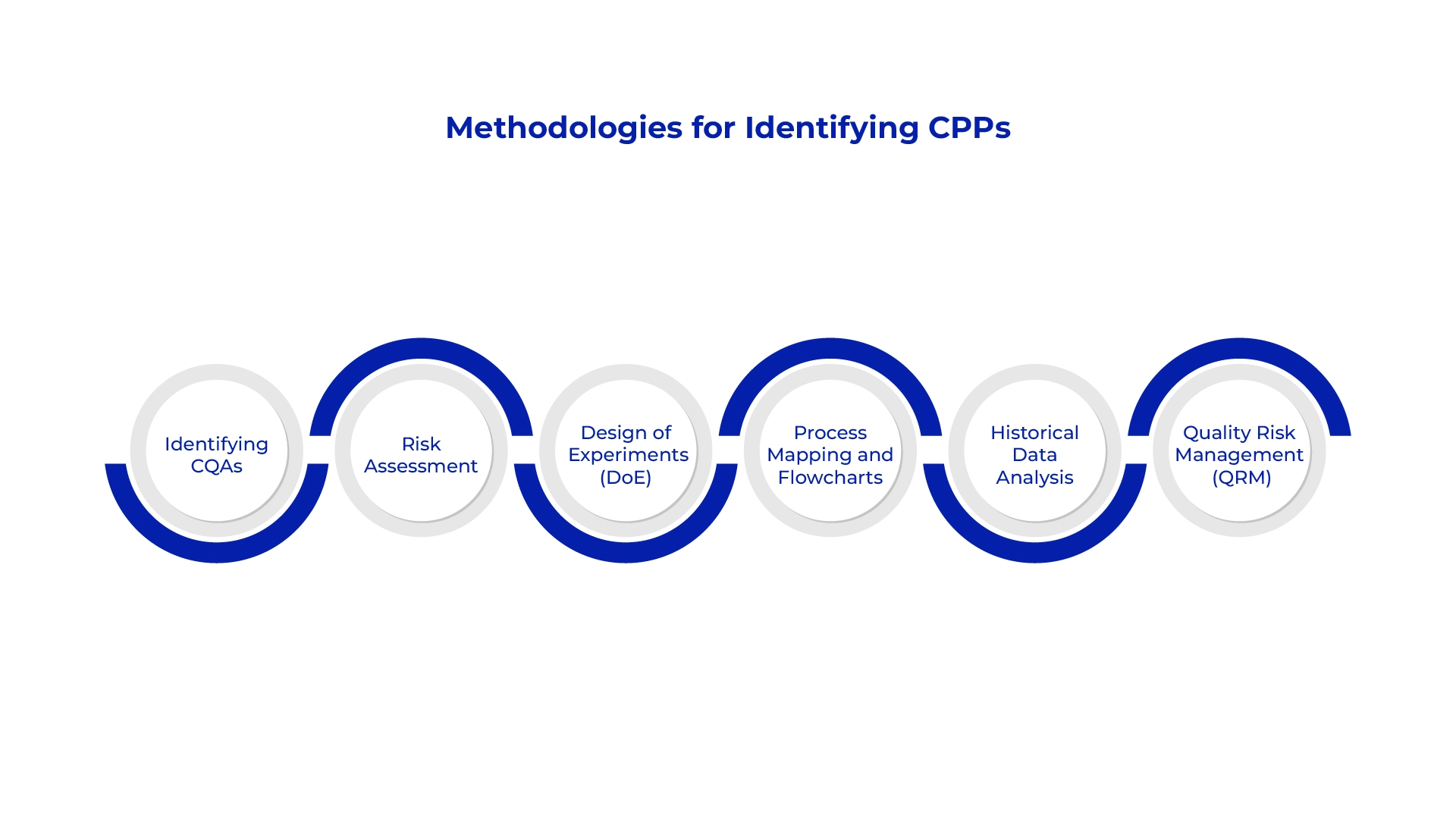

Methodologies for Identifying CPPs

Identifying CPPs involves a systematic approach that includes the following steps:

- Identifying CQAs: The first step is to identify the critical quality attributes of the product. These attributes are crucial for ensuring the product’s efficacy, safety, and quality.

- Risk Assessment: Perform a risk assessment to determine which process parameters have a significant impact on CQAs. Tools such as Failure Mode and Effects Analysis (FMEA) and Ishikawa diagrams can be used.

- Design of Experiments (DoE): This statistical method helps in understanding the relationship between process parameters and CQAs by evaluating multiple parameters simultaneously.

- Process Mapping and Flowcharts: Detailed mapping of the manufacturing process helps in identifying potential CPPs at each stage of production.

- Historical Data Analysis: Analyzing historical production data can provide insights into which parameters have previously impacted product quality.

- Quality Risk Management (QRM): Incorporating QRM frameworks to systematically evaluate and control risks associated with CPPs.

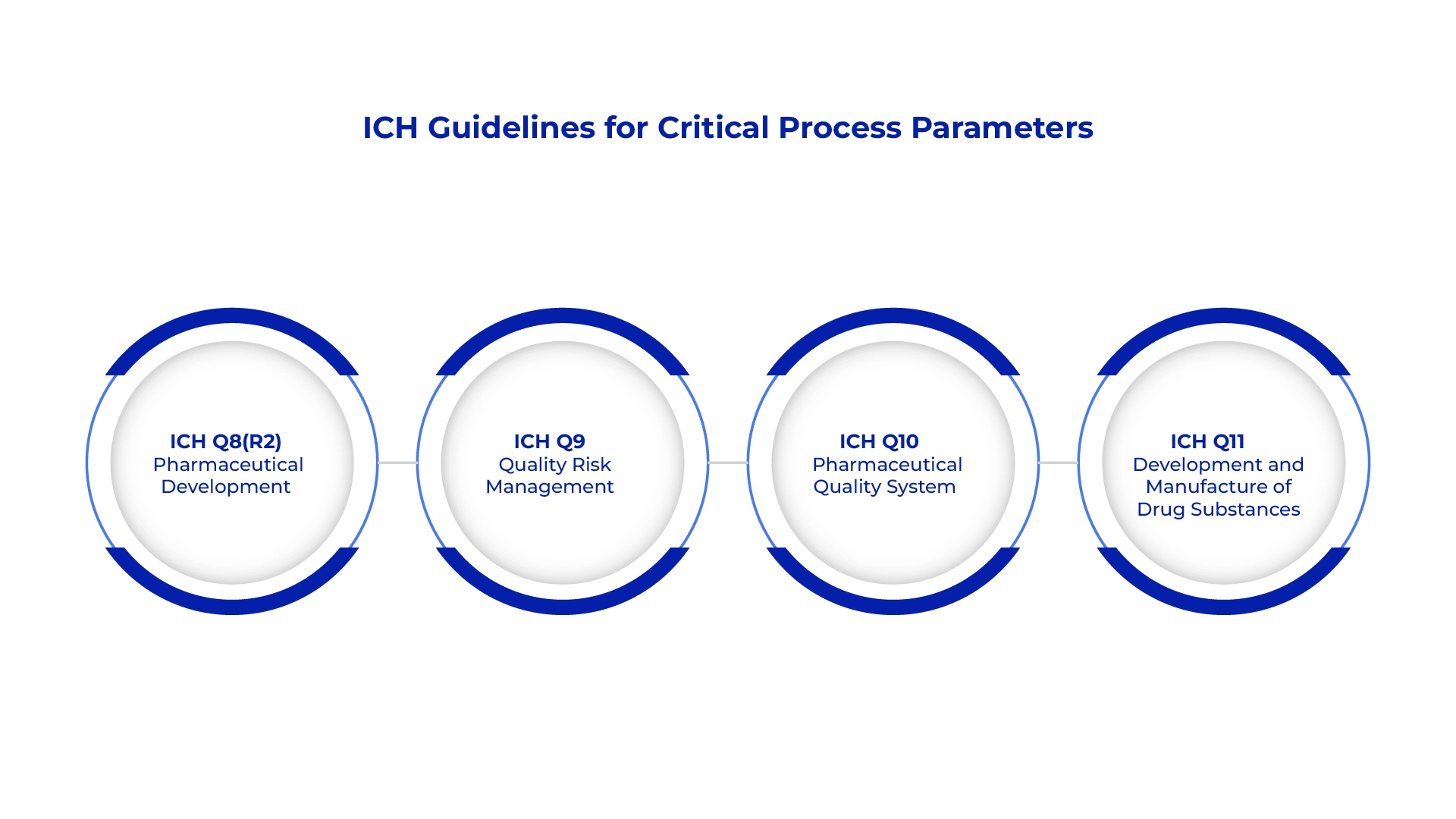

ICH Guidelines for Critical Process Parameters

The ICH provides comprehensive guidelines for pharmaceutical development and manufacturing, including the management of CPPs:

- ICH Q8(R2) – Pharmaceutical Development: This guideline emphasizes a systematic approach to pharmaceutical development, highlighting the importance of identifying and controlling CPPs to ensure product quality.

- ICH Q9 – Quality Risk Management: It provides principles and examples of tools for quality risk management that can be applied to the identification and control of CPPs.

- ICH Q10 – Pharmaceutical Quality System: This guideline establishes a framework for an effective pharmaceutical quality system, integrating quality risk management and continuous improvement, both crucial for managing CPPs.

- ICH Q11 – Development and Manufacture of Drug Substances: This focuses on the development and manufacture of drug substances, providing guidance on process control strategies, including the identification and management of CPPs.

The Role of MES in CPP Compliance

A Manufacturing Execution System (MES) is instrumental in achieving CPP compliance. It offers real-time monitoring and control, swiftly detecting deviations from CPPs and enabling corrective actions. Additionally, MES automates and standardizes processes, reducing errors and ensuring consistent adherence to CPPs. By consolidating and analyzing manufacturing data, MES provides insights for process optimization. Furthermore, its integration with Quality Management Systems enhances product traceability and compliance. Overall, MES supports continuous improvement, ensuring sustained quality, regulatory compliance, and patient safety.

Real-time Data Acquisition and Monitoring: MES integrates with sensors and IoT devices on the shop floor to collect real-time data on critical process parameters such as temperature, pressure, flow rate, and more. This allows for centralized monitoring through a dashboard where operators can monitor CPPs in real-time, ensuring immediate visibility into the manufacturing process.

Data Analysis and Reporting: MES software not only conducts trend analysis by scrutinizing historical and real-time data to pinpoint trends and deviations from desired parameters but also automates reporting, producing thorough reports on Critical Process Parameters (CPPs) to ensure quality assurance, compliance, and facilitate continuous improvement efforts.

Process Control and Automation; MES integrates with PLCs (Programmable Logic Controllers) and other automation systems to automatically adjust processes when CPPs deviate from the set parameters. This includes implementing feedback control mechanisms to maintain CPPs within specified limits, reducing variability, and enhancing consistency.

Quality Management: MES utilizes Statistical Process Control (SPC) techniques to monitor and control Critical Process Parameters (CPPs), ensuring processes remain within control limits and identifying trends that could lead to deviations. It also sets up alerts and alarms for when CPPs approach or exceed acceptable thresholds, enabling a quick response to potential issues.

Recipe and Batch Management: MES manages recipes and batch processes to ensure that each production run adheres to predefined parameters, maintaining consistency across batches, while also tracking and managing changes to process parameters and recipes, ensuring that any adjustments are controlled and documented.

Traceability and Compliance: Maintains comprehensive records of all process parameters and changes, providing complete audit trails for Critical Process Parameters (CPPs). This ensures traceability, regulatory compliance, and quality assurance by documenting every aspect of the production process and any modifications made.

Workforce Empowerment: MES delivers real-time instructions and guidance to operators based on current CPPs, ensuring that manual interventions are consistent and accurate. Additionally, it provides training modules and support to help operators understand the importance of CPPs and how to manage them effectively. This dual approach ensures that operators are well-informed and capable of maintaining process parameters within desired limits.

Integration with Other Systems: MES integrates with Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) systems to ensure seamless data flow and consistency across the organization. This integration helps in coordinating with suppliers and customers to ensure that raw materials and finished products meet the required specifications, enhancing overall supply chain efficiency and product quality.

Continuous Improvement and Performance Metrics

Supports continuous improvement initiatives like Kaizen and Six Sigma by providing data and insights necessary for identifying and eliminating process inefficiencies. MES tracks key performance indicators (KPIs) related to CPPs, aiding in ongoing process optimization and ensuring continuous enhancement of manufacturing processes.

The ability to precisely control and optimize Critical Process Parameters is crucial in the pharmaceutical industry for ensuring product quality, regulatory compliance, and operational efficiency. A Manufacturing Execution System (MES) provides the tools and capabilities necessary to achieve these goals through real-time monitoring, automated process control, comprehensive data analysis, and robust quality management.

By leveraging the capabilities of MES, pharmaceutical manufacturers can ensure that their products consistently meet the highest standards of quality and safety, maintaining compliance with regulatory requirements and enhancing overall manufacturing performance. Other common tools and techniques for real-time monitoring and control of CPPs in pharmaceutical manufacturing include Process Analytical Technology (PAT) with tools like NIR and Raman Spectroscopy, Automated Control Systems such as DCS, and Real-Time Release Testing (RTRT) for ensuring product quality before release.

References

- Wikipedia on Critical Process Parameters (Wikipedia)

- “Using a Systematic Approach to Select Critical Process Parameters” on Pharmaceutical Technology (PharmTech)

- How to Identify Critical Process Parameters” by DSI InPharmatics (DSI InPharmatics)