In the fast-evolving landscape of pharmaceutical manufacturing, precision, compliance, and efficiency reign supreme. Traditionally, the industry relied on labor-intensive paper-based batch record systems, laden with challenges ranging from manual data entry errors to regulatory compliance burdens. However, the advent of Electronic Batch Record (EBR) software has sparked a digital revolution, transforming how pharmaceutical companies manage and document their manufacturing processes.

Understanding Electronic Batch Record Software

EBR software represents the pinnacle of modern manufacturing technology. It’s a digital powerhouse designed to revolutionize how businesses manage their batch manufacturing processes. By replacing antiquated paper-based systems with a dynamic electronic platform, EBR software ushers in a new era of efficiency, compliance, and operational excellence.

Challenges of Paper-Based Batch Record Management in Pharma

For decades, pharmaceutical companies grappled with the limitations of paper-based batch record systems:

Manual Data Entry: Transcribing data from equipment and logs into paper records was prone to errors and time-consuming.

Version Control Issues: Managing multiple paper copies led to version discrepancies and the risk of using outdated information.

Limited Accessibility: Retrieving paper records from physical archives was cumbersome and inefficient.

Regulatory Compliance Burden: Ensuring compliance required meticulous documentation and auditing processes, adding to administrative overheads.

The Digital Revolution: Embracing Electronic Batch Record Software

Recognizing the inefficiencies of paper-based systems, pharmaceutical companies are turning to EBR software for its transformative capabilities:

Real-Time Data Capture: EBR software enables real-time monitoring and recording of critical process parameters, reducing manual errors and ensuring data accuracy.

Automated Workflows: Customizable workflows guide operators through each step, ensuring compliance with SOPs and minimizing deviations.

Centralized Document Management: EBR systems centralize document storage, providing easy access while ensuring version control and regulatory compliance.

Electronic Signatures: Built-in electronic signatures streamline approval processes, ensuring compliance with regulations while maintaining data integrity and security.

Enhanced Compliance: EBR software automates compliance documentation, facilitating regulatory audits and reducing the risk of non-compliance penalties.

Challenges of Implementing Electronic Batch Record (EBR) Software

Transitioning to EBR software presents unique challenges for pharmaceutical companies:

Resistance to Change: Employees may resist the transition from familiar paper-based systems to digital solutions, requiring effective change management strategies.

Data Migration: Migrating data from legacy systems to EBR software can be complex and time-consuming, requiring careful planning and execution.

Integration Issues: Ensuring seamless integration with existing manufacturing systems and equipment poses technical challenges that need to be addressed.

Training Requirements: Comprehensive training programs are essential to ensure employees are proficient in using EBR software and understand its functionalities.

Regulatory Compliance: Meeting regulatory requirements, such as FDA’s 21 CFR Part 11, adds complexity to implementation and necessitates thorough validation processes.

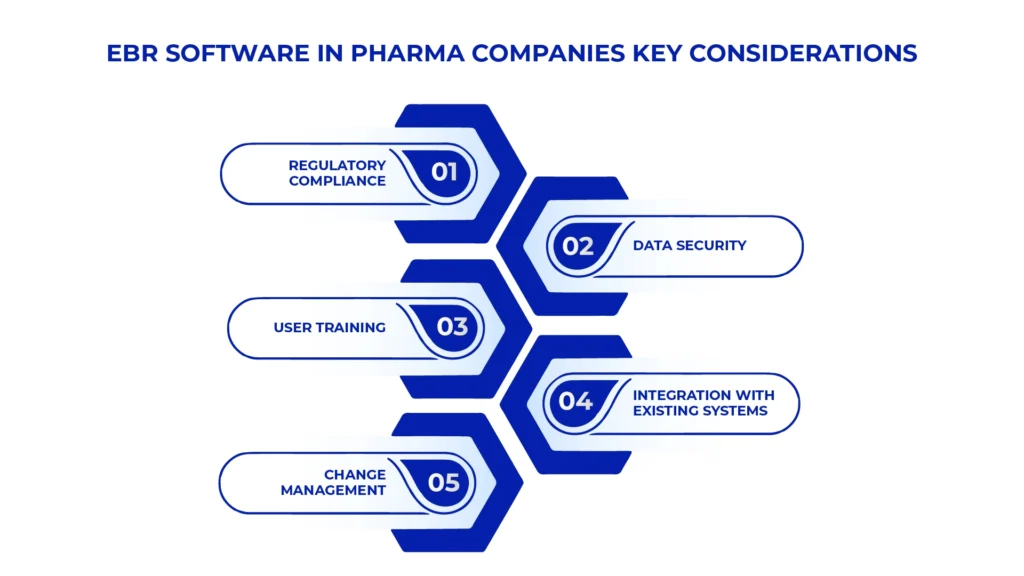

Key Considerations of Implementing Electronic Batch Record (EBR) Software in Pharma Companies

Transitioning to EBR software requires careful planning and execution:

Regulatory Compliance: Choose EBR software compliant with industry regulations like FDA’s 21 CFR Part 11 to ensure data integrity and regulatory compliance.

Data Security: Implement robust security measures to protect sensitive manufacturing data from breaches.

User Training: Provide comprehensive training to employees to ensure smooth adoption and utilization of EBR software.

Integration with Existing Systems: Evaluate compatibility and integration capabilities to ensure seamless data exchange.

Change Management: Implement effective strategies to address resistance and promote organizational buy-in for digital transformation.

Best Practices for Transitioning to Electronic Batch Record (EBR) software for Pharmaceutical Companies

Transitioning to Electronic Batch Record (EBR) software is a significant undertaking for pharmaceutical companies, requiring careful planning, execution, and adherence to best practices. Here are some key best practices to consider:

Develop a Comprehensive Implementation Plan: Create a detailed implementation plan that outlines specific goals, timelines, roles and responsibilities, resource requirements, and milestones. This plan should address all aspects of the transition, from data migration to user training and validation.

Gain Executive Support: Secure buy-in from senior management and key stakeholders early in the process. Executive support is crucial for allocating resources, overcoming resistance to change, and driving organizational alignment throughout the transition.

Conduct a Thorough Needs Assessment: Before selecting an EBR solution, conduct a comprehensive needs assessment to identify specific requirements, challenges, and objectives. Consider factors such as scalability, regulatory compliance, integration capabilities, and user experience.

Select the Right EBR Solution: Choose an EBR solution that aligns with your company’s needs, regulatory requirements, and long-term strategic goals. Evaluate potential vendors based on factors such as functionality, flexibility, scalability, regulatory compliance, reputation, and support services.

Prioritize Data Migration and Integration: Plan and execute data migration from existing systems to the new EBR software meticulously. Ensure compatibility and seamless integration with existing manufacturing systems, equipment, and databases to minimize disruption and data discrepancies.

Invest in User Training and Change Management: Provide comprehensive training programs for employees to ensure they are proficient in using the new EBR software. Develop change management strategies to address resistance to change and foster organizational buy-in for digital transformation.

Implement Robust Validation Processes: Validate the EBR software thoroughly to ensure it meets regulatory requirements and performs as intended. Develop validation protocols, conduct testing, document results, and obtain necessary approvals from regulatory authorities.

Establish Data Security Measures: Implement robust data security measures to protect sensitive manufacturing data from unauthorized access, breaches, and cyber threats. Ensure compliance with data privacy regulations and industry standards for data security.

Monitor Performance and Continuous Improvement: Continuously monitor the performance of the EBR software and solicit feedback from users to identify areas for improvement. Implement updates, enhancements, and optimizations to maximize the value and efficiency of the EBR system over time.

Maintain Regulatory Compliance: Stay abreast of changes in regulatory requirements and ensure ongoing compliance with relevant standards, such as FDA’s 21 CFR Part 11. Regularly review and update procedures, documentation, and training programs to reflect current regulatory expectations.

EBR Software Functionality & Features

Real-Time Data Capture: EBR software empowers operators with real-time insights, allowing for instant monitoring and documentation of critical process parameters.

Automated Workflows: Customizable workflows guide operators through each step of the manufacturing process, ensuring compliance with SOPs and minimizing deviations.

Centralized Document Management: EBR systems centralize document storage, providing easy access while ensuring version control and regulatory compliance.

Electronic Signatures: Built-in electronic signatures streamline approval processes, ensuring compliance with regulations while maintaining data integrity and security.

Enhanced Compliance: EBR software automates compliance documentation, facilitating regulatory audits and reducing the risk of non-compliance penalties.

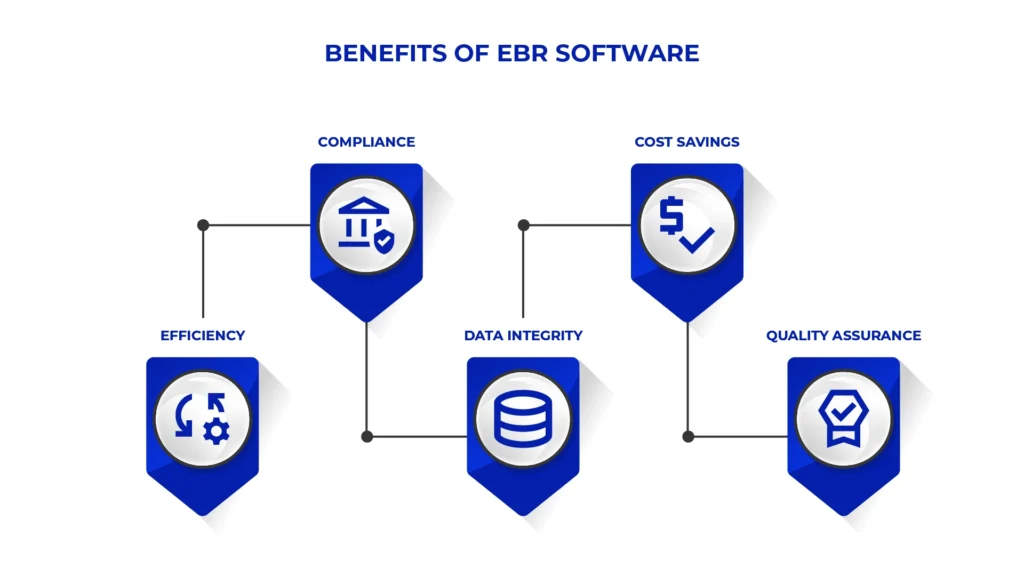

Benefits of EBR Software

The adoption of EBR software brings a multitude of benefits to pharmaceutical companies:

Efficiency: Real-time data capture and automated workflows accelerate manufacturing processes, reducing downtime and improving overall efficiency.

Compliance: Automated compliance documentation ensures adherence to regulatory standards, reducing the risk of errors and non-compliance penalties.

Data Integrity: Centralized document management and electronic signatures ensure data integrity, providing a secure and reliable audit trail.

Cost Savings: Eliminating paper-based processes reduces administrative overheads associated with printing, storage, and manual data entry.

Quality Assurance: Real-time monitoring and proactive deviation detection enhance product quality and consistency, safeguarding brand reputation.

The Future of Manufacturing: Leveraging Electronic Batch Record Software for Success

As manufacturing processes continue to evolve, the role of EBR software will become increasingly vital. With advancements in technology such as IoT integration, machine learning, and predictive analytics, EBR software will enable manufacturers to achieve new levels of efficiency, quality, and regulatory compliance. By embracing innovation and leveraging EBR software, manufacturers can future-proof their operations and stay ahead of the competition.