Efficiency and precision are quintessential aspects in the life sciences and pharmaceutical industries. They help companies attain business process excellence departing from traditional manual processes that previously were the cornerstone of production. As technology has advanced, manual processes have taken a backseat. Owing to multiple challenges faced due to manual processes, companies are adopting technological solutions, meeting the demands of the modern industry. The advent of Electronic Batch Records (EBR) is transformative, promising to revolutionize manufacturing operations by seamlessly integrating with equipment and overcoming the hurdles posed by manual processes.

Understanding EBR: A Paradigm Shift in Manufacturing

Traditionally businesses relied on paper-based documentation methods that were prone to errors and data losses. Electronic Batch Manufacturing Records represent a departure from conventional documentation method, streamlining the process while enhancing efficiency and accuracy. EBR encompasses digital records entailing all manufacturing processes, from raw material tracking to equipment utilization and quality control. Unlike manual record, EBRs offer real-time data capture, analysis, and reporting capabilities, providing manufacturers with unparalleled visibility and control over their operations. The system’s integration with equipment and other systems helps in accurate data collection and recording for achieving business process excellence.

Integration with Equipment: Enhancing Efficiency, Diminishing Challenges

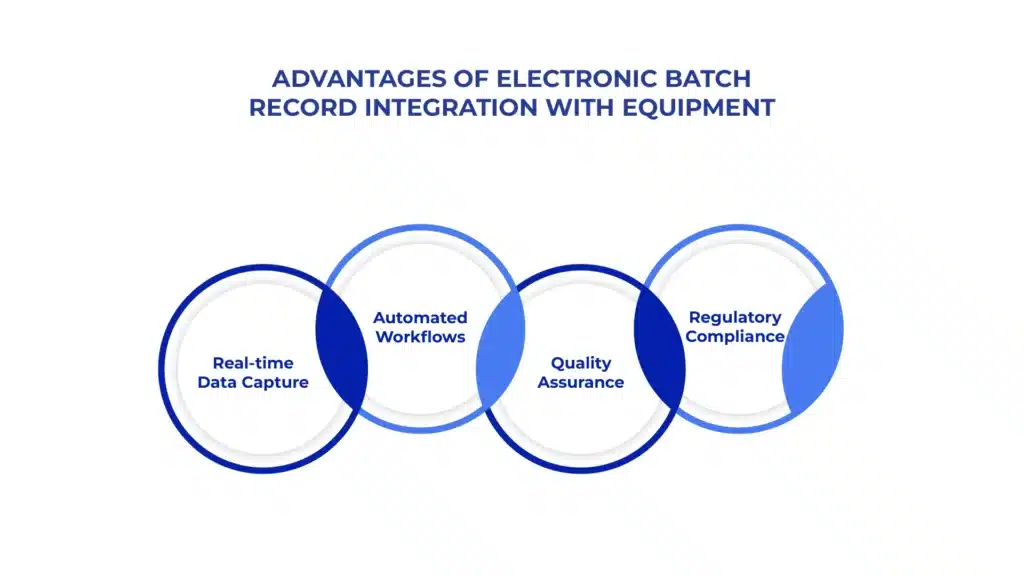

One of the significant advantages of Electronic Batch Records (EBR) is seamless integration with varied manufacturing equipment that helps in easy collection and tracking of data. By interfacing directly with machinery and systems, EBR streamlines data collection, reduces manual intervention, and minimizes the risk of human error. This integration facilitates:

Real-time Data Capture

Electronic Batch Records can directly capture data from equipment sensors and controllers. This ensures accurate and immediate data collection and also provides real-time data that enables proactive decision-making, optimization of processes, and rapid response to deviations or anomalies.

Automated Workflows

Equipment integration in EBR systems enables automated workflows, eliminating the need for manual data entry and streamlining the production processes. Tasks such as recipe execution, batch tracking and equipment monitoring are automated, enhancing efficiency, accuracy and reducing cycle times.

Quality Assurance

Electronic Batch Records (EBR) facilitate comprehensive quality control by continuously monitoring equipment performance and process parameters. Any deviations from predefined specifications trigger immediate alerts, allowing for prompt corrective action and ensuring product quality and consistency.

Regulatory Compliance

In regulated industries such as pharmaceuticals and food production, compliance with stringent quality and safety standards is non-negotiable. Electronic Batch Records simplify compliance by maintaining detailed electronic records of manufacturing processes, facilitating audits, and demonstrating adherence to regulatory requirements.

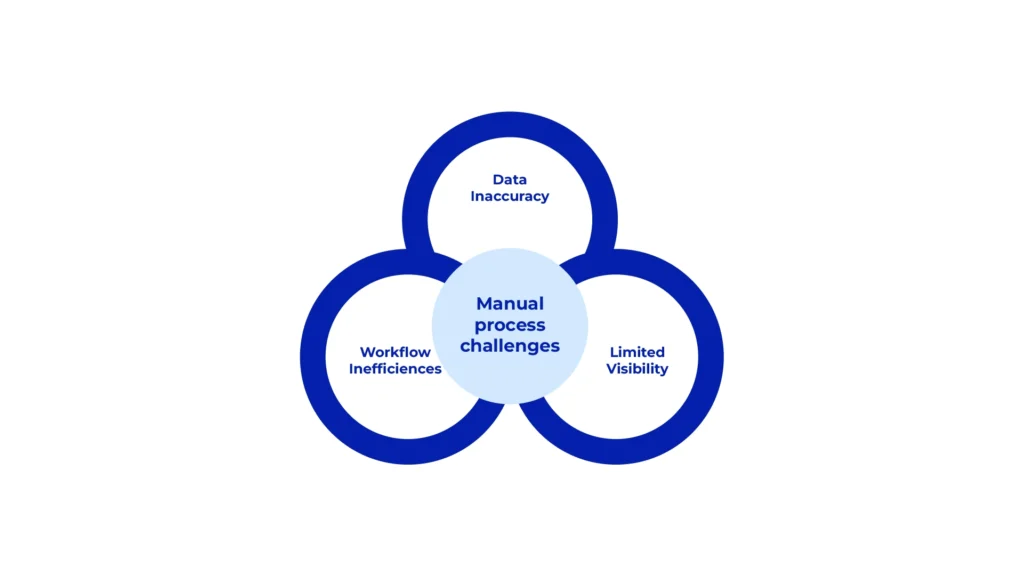

Overcoming Manual Process Challenges

The integration of Electronic Batch Records (EBR) with equipments addresses several challenges inherent in manual manufacturing processes. Some of the addressed challenges are mentioned below.

Data Inaccuracy

Manual data entry is prone to errors, leading to discrepancies in records and compromised product quality. Electronic Batch Records with their automated data capture capabilities, minimize the risk of errors and ensure the accuracy of information.

Workflow Inefficiencies

Manual processes are inherently slower and more labour-intensive, resulting in inefficiencies and increased production costs. By automating workflows and reducing manual intervention, Electronic Batch Records integration streamlines operations, improves productivity, and enhances resource utilization.

Limited Visibility

Manual record-keeping leads to limited visibility into production processes, making it difficult to identify inefficiencies or performance bottlenecks. EBRs provide real-time insights into equipment performance, process trends, and production metrics, empowering manufacturers to make data-driven decisions and optimize operations proactively.

Embracing the Future of Manufacturing with EBR Integration

The integration of Electronic Batch Records (EBR) with equipment is transformational in production processes of the modern age. EBRs enable manufacturers to overcome hurdles posed by manual processes and unlock new levels of efficiency, quality and agility leveraging the power of real-time data, automation and connectivity. As industries continue to embrace digital transformation, EBR integration stands as an ideal solution for modern manufacturing, driving innovation and excellence in the pursuit of operational excellence.