In the realm of pharmaceutical manufacturing, achieving precision, compliance, and operational efficiency is of utmost importance. To fulfill these requirements, the industry has embraced Manufacturing Execution Systems (MES) as a fundamental technological solution. This article delves into the seamless integration of MES within the pharmaceutical sector, encompassing its historical evolution, essential components, operational functions, diverse terminology, and specialized variants tailored for Pharma MES. Additionally, it explores how MES solutions, such as AmpleLogic MES, adeptly navigate and resolve the distinctive challenges encountered in the pharmaceutical industry.

Understanding Manufacturing Execution System in Pharmaceutical Industry

The Manufacturing Execution System (MES) has emerged as a vital tool for optimizing production processes in the pharmaceutical sector. At its core, MES serves as a bridge between enterprise resource planning (ERP) systems and shop floor operations. It enables real-time monitoring, control, and optimization of manufacturing activities, ensuring compliance with regulatory standards while enhancing efficiency and productivity.

Evolution of MES in Pharma

The roots of MES in pharmaceuticals dates back to the 1980s when industries began adopting computerized systems to streamline production processes. However, the pharmaceutical sector faced unique challenges due to stringent regulations and complex operations. Over time, specialized MES solutions emerged, offering features like electronic batch records, real-time monitoring and comprehensive traceability to address these challenges. These innovations marked a significant shift towards digitalization in pharmaceutical manufacturing, enabling greater efficiency, compliance and accountability throughout the production lifecycle. Today, MES continues to evolve, integrating advanced technologies to further optimize pharmaceutical operations and drive innovation in the industry.

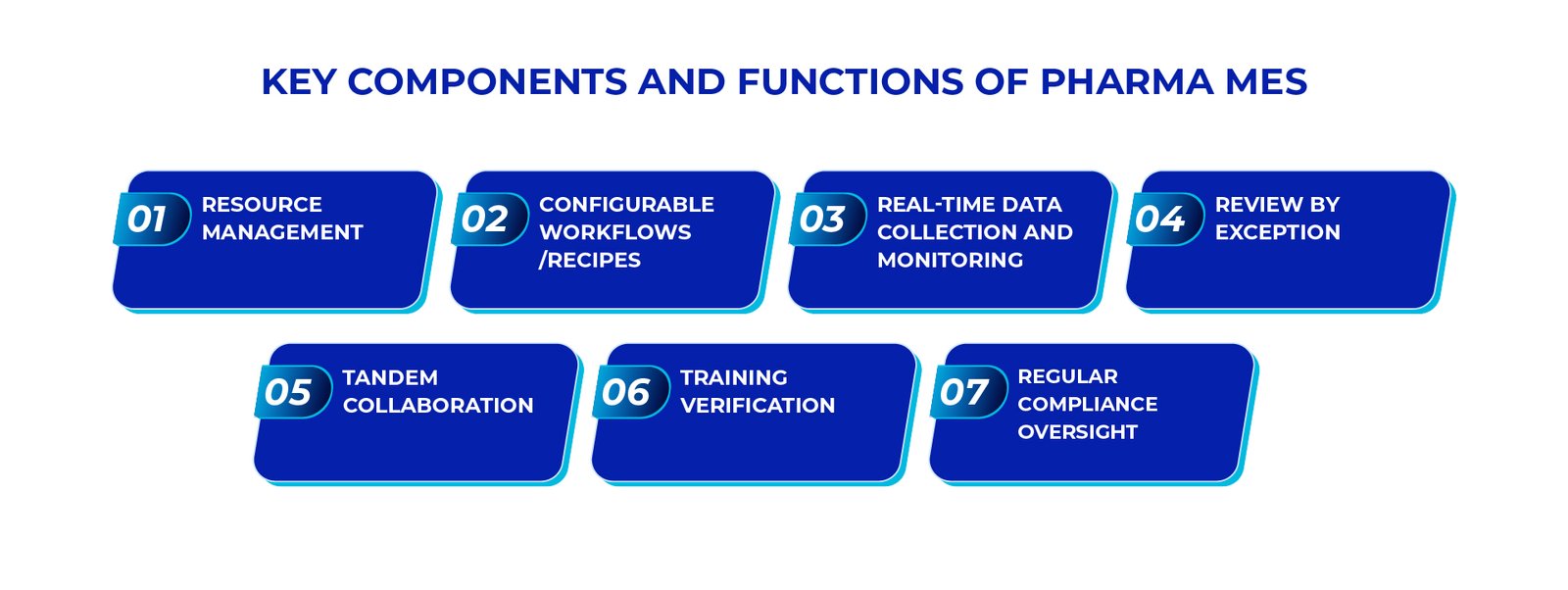

Key Components and Functions of Pharma MES

Resource Management: Efficient allocation and utilization of equipment and materials is facilitated with an MES system, ensuring seamless production workflows.

Configurable Workflows/Recipes: MES offers end-user configurable workflows and recipes, enabling tailored processes to meet specific manufacturing requirements.

Real-Time Data Collection and Monitoring: MES systems provide real-time insights into production processes, allowing for immediate intervention and optimization.

Review by Exception: Exception-based monitoring ensures that only deviations from predefined parameters are flagged for review, minimizing manual oversight.

Tandem Collaboration: MES fosters collaboration across teams and sites, promoting communication and alignment throughout the manufacturing process.

Training Verification: MES verifies employee training and qualifications, ensuring that only trained personnel perform critical tasks.

Regular Compliance Oversight: Continuous monitoring and documentation ensure adherence to regulatory standards, minimizing compliance risks.

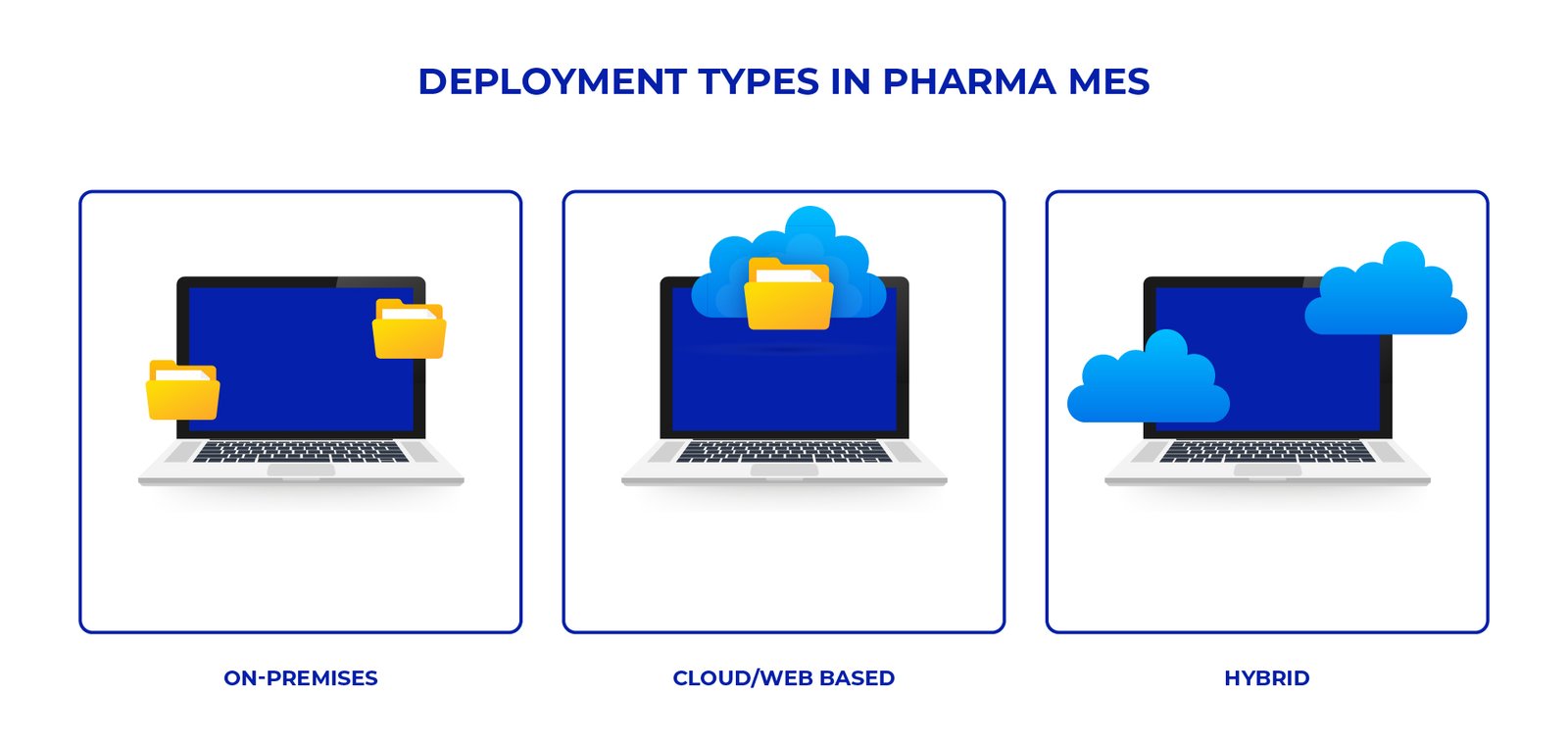

Deployment Types in Pharma MES

In addition to its features and functionalities, understanding the deployment options available for Pharma MES is crucial. Common deployment types include on-premises installations, cloud-based solutions, and hybrid models. On-premises deployments involve hosting the MES software within the organization’s own infrastructure, providing full control over data management and security but requiring significant upfront investment in hardware and maintenance. Cloud-based solutions, on the other hand, offer flexibility and scalability, with the software hosted on remote servers and accessible via the internet. This model reduces the need for upfront investment in hardware and allows for easier upgrades and updates but may raise concerns about data security and regulatory compliance. Hybrid deployments combine elements of both on-premises and cloud-based solutions, offering a balance between control and flexibility. Understanding these deployment options enables pharmaceutical companies to choose the approach that best suits their specific requirements, budget and regulatory considerations.

Alternative Names and Variants of Pharma MES

Pharma MES play a vital role in modernizing pharmaceutical manufacturing operations. These systems are also referred as

- Pharma MES Systems

- Pharma MES Software

- MES in Pharma

- Digital Manufacturing in Pharma

- Cloud Based MES

- Manufacturing Operations Management Systems (MOMS)

- Electronic Batch Record System (EBRS)

- Electronic Batch Records

- Master Batch Records (MBR)

- Manufacturing Execution System (MES)

- Manufacturing Execution Systems (MES) Software

- MES Software

These are synonymous with Pharma MES, reflecting its diverse functionalities and applications.

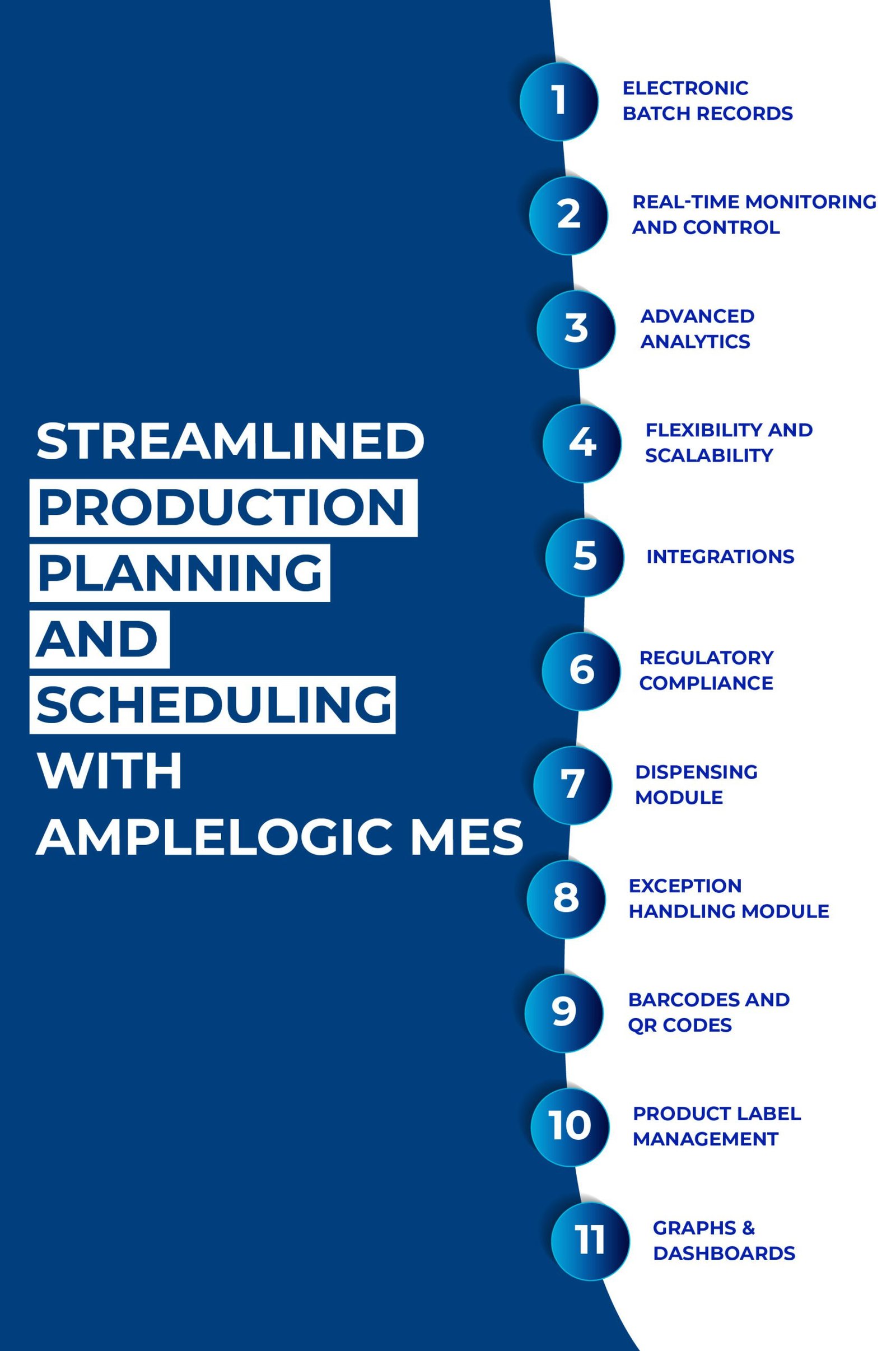

AmpleLogic MES: Revolutionizing Pharmaceutical Manufacturing

AmpleLogic MES stands as a testament to the transformative potential of Manufacturing Execution Systems (MES) in the pharmaceutical industry. With its robust functionality, AmpleLogic MES is reshaping pharmaceutical manufacturing processes by streamlining operations and enhancing efficiency.

Here’s a comprehensive look at its key features:

Electronic Batch Records: AmpleLogic MES replaces cumbersome paper-based batch records with electronic documentation ensuring accuracy and compliance. This feature streamlines documentation processes, reduces errors, and enhances traceability throughout the production lifecycle.

Real-Time Monitoring and Control: Providing unparalleled visibility into production processes, AmpleLogic MES empowers manufacturers to monitor equipment performance, track production metrics, and promptly address deviations or issues. With real-time insights, manufacturers can optimize resource allocation, minimize downtime, and maximize productivity.

Advanced Analytics: AmpleLogic MES offers powerful analytics tools for actionable insights into production performance. By leveraging data analytics, manufacturers can identify trends, predict potential issues, and continuously improve manufacturing processes. This data-driven approach enables informed decision-making and fosters operational excellence.

Graphs & Dashboards: AmpleLogic MES provides enhanced graphical representation depicting critical manufacturing data, ranging from production rates and equipment performance to quality metrics and compliance statuses. By leveraging MES graphs and dashboards, pharmaceutical companies can swiftly monitor operations, identify trends, detect anomalies, and make informed decisions to optimize processes, ensuring quality and compliance.

Flexibility and Scalability: AmpleLogic MES is highly configurable to accommodate the unique requirements of different pharmaceutical manufacturing operations. It supports configurable workflows, user roles, and process parameters, allowing for easy customization and scalability. Whether adapting to changes in production processes or scaling operations, AmpleLogic MES ensures flexibility and agility.

Integrations: AmpleLogic MES seamlessly integrates with other enterprise systems such as Enterprise Resource Planning (ERP) systems, Laboratory Information Management Systems (LIMS), and Quality Management Systems (QMS). This interoperability enables smooth data exchange, streamlines operations, and enhances overall efficiency across the organization.

Regulatory Compliance: AmpleLogic MES supports compliance with regulatory bodies such as the Food and Drug Administration (FDA), European Medicines Agency (EMA), and other global regulatory authorities. With features like electronic signatures and audit trails, AmpleLogic MES ensures adherence to regulatory standards and facilitates regulatory audits with ease.

Dispensing Module: AmpleLogic MES includes a dispensing module that manages the dispensing of materials and ingredients required for pharmaceutical manufacturing. This module ensures accurate dispensing, minimizes waste, and maintains inventory integrity throughout the production process.

Exception Handling Module: AmpleLogic MES incorporates an exception handling module to identify and address deviations or anomalies in production processes. This module enables proactive problem-solving, minimizing disruptions and ensuring consistent product quality.

Barcodes and QR Codes: AmpleLogic MES utilizes barcodes and QR codes for efficient tracking and identification of materials, products, and batches throughout the manufacturing process. This automated identification system enhances traceability, reduces errors, and streamlines data capture.

Product Label Management: AmpleLogic MES includes a product label management feature that ensures accurate and compliant labeling of pharmaceutical products. This feature enables dynamic generation and printing of labels, incorporating product information, regulatory requirements and variable data as needed.

Conclusion

In conclusion, Manufacturing Execution Systems (MES) have become indispensable in the pharmaceutical industry, offering a comprehensive solution to address the challenges of compliance, efficiency and quality control. AmpleLogic MES, along with other MES solutions, is at the forefront of this transformation, empowering pharmaceutical manufacturers to streamline operations, improve productivity, and deliver high-quality products to market faster and more efficiently than ever before.